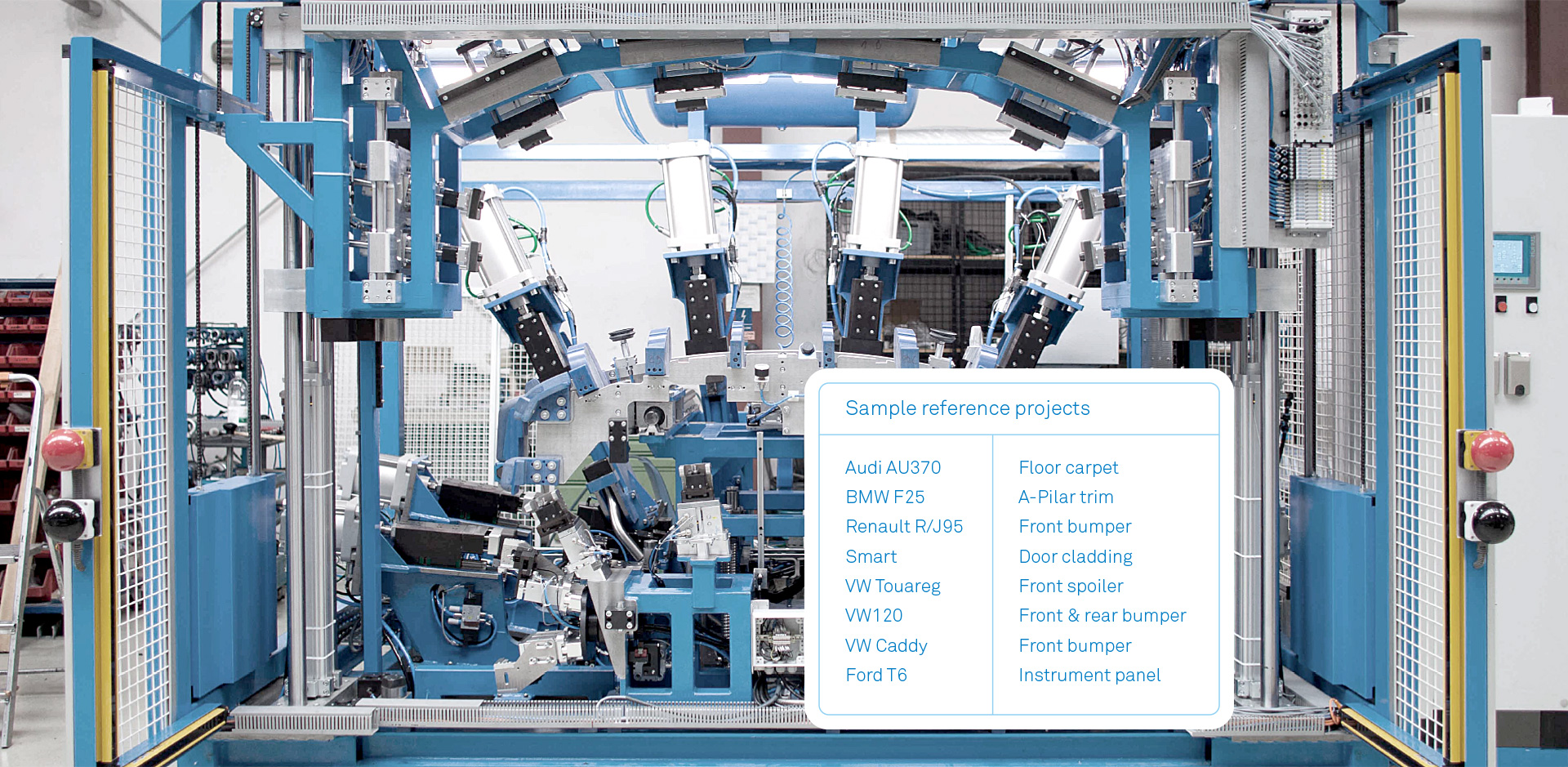

Punching & trimming machines

Alternate technologies, many possibilities.

- Hydraulic, pneumatic, pneumo-hydraulic or manual drives.

- Ultra-sonic, hot or cold knife punching.

- Direct “on-die” or transfer loading.

- One step radius and/or chamfer embossing.

- Addition of downstream processes such as sticking, US welding or assembly clipping in one machine.

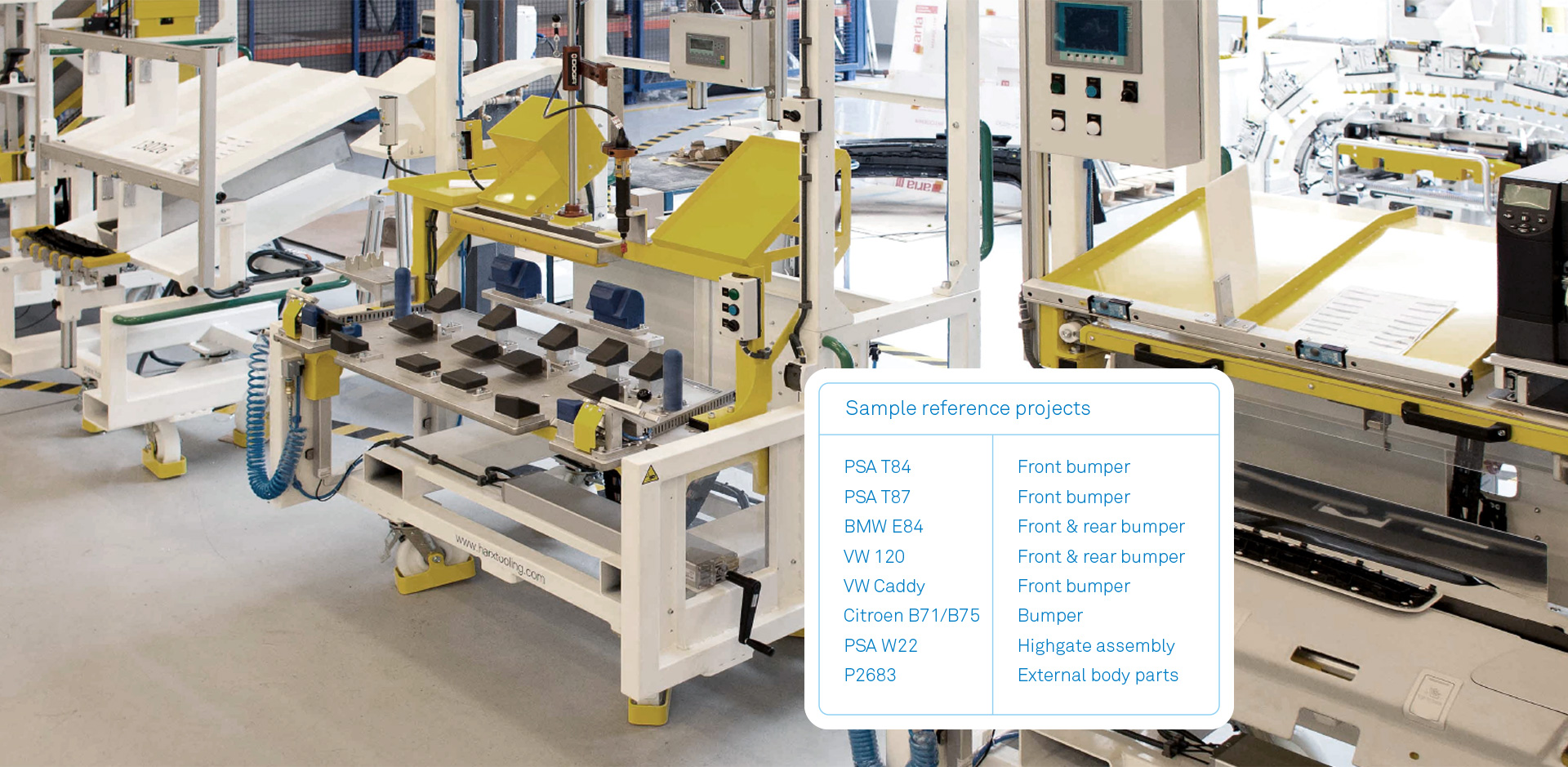

Assembly stations

Perfect tools for error free assembly.

- Part retention and counterforce blocks tailored to assembly requirements including unique cast resin technology for protection of fragile or painted parts.

- Poke-yoke operator assistance ranging from “pick to light” sensors to automatic part detection via optical sensors or camera applications.

- Integrated functions such as PLC assisted screwing, stapling, riverting, continuity tests, barcode scanning and label printing.

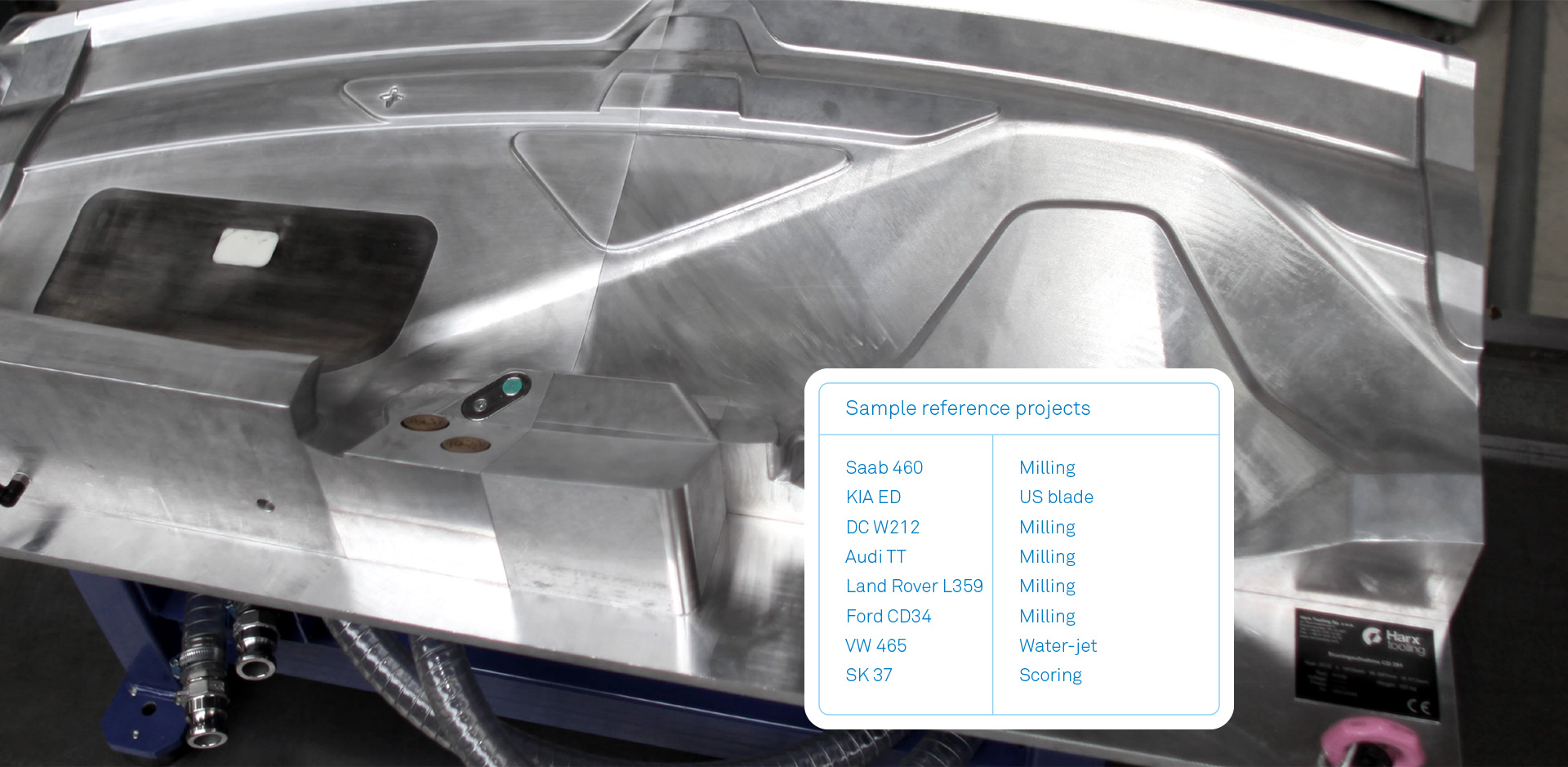

Fixtures

Perfect fit. Repeatable results.

- Milling, scoring, US blade and water-jet fixtures for use with flexible robotic systems.

- A-side or B-side retention via vacuum or pneumo-mechanical clamping circuits.

- Aluminum, resin block, cast resin or laminate nests.

- Suitable for thermoplastic, composite and insulation parts.

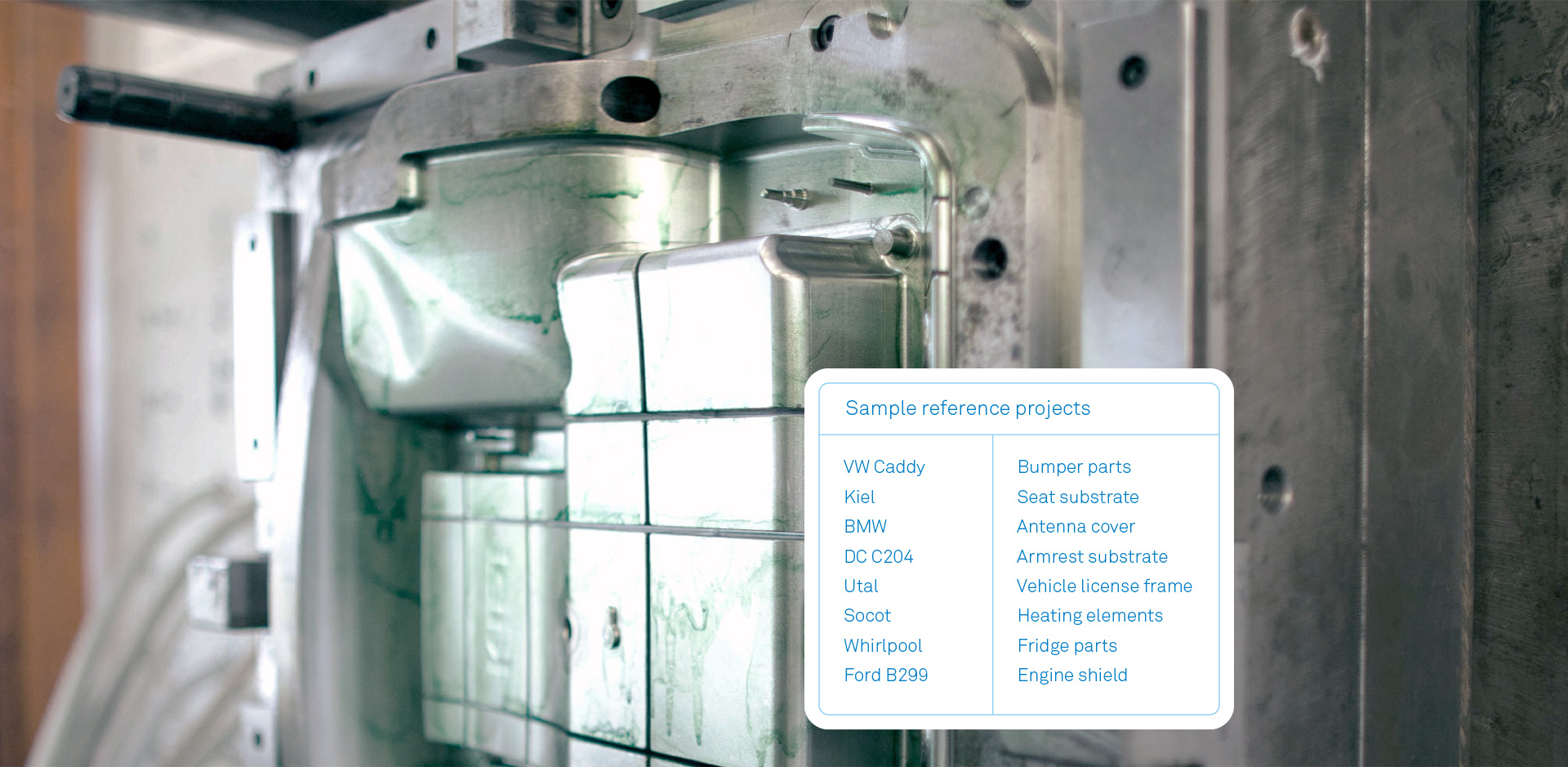

Injection tools

Thermoplastics & Duroplastics. Always in form.

- High pressure, thermoplastic injection moulds supplied with industry leading hot runner systems.

- Low pressure injection moulds for RIM, SRIM or DCDP (Telene).

- Mechanical or hydraulic sliders in straight or angled configurations.

- Modifications of existing tools with laser welding support.

- Capabilities of manufacturing tools up to 16 tons.

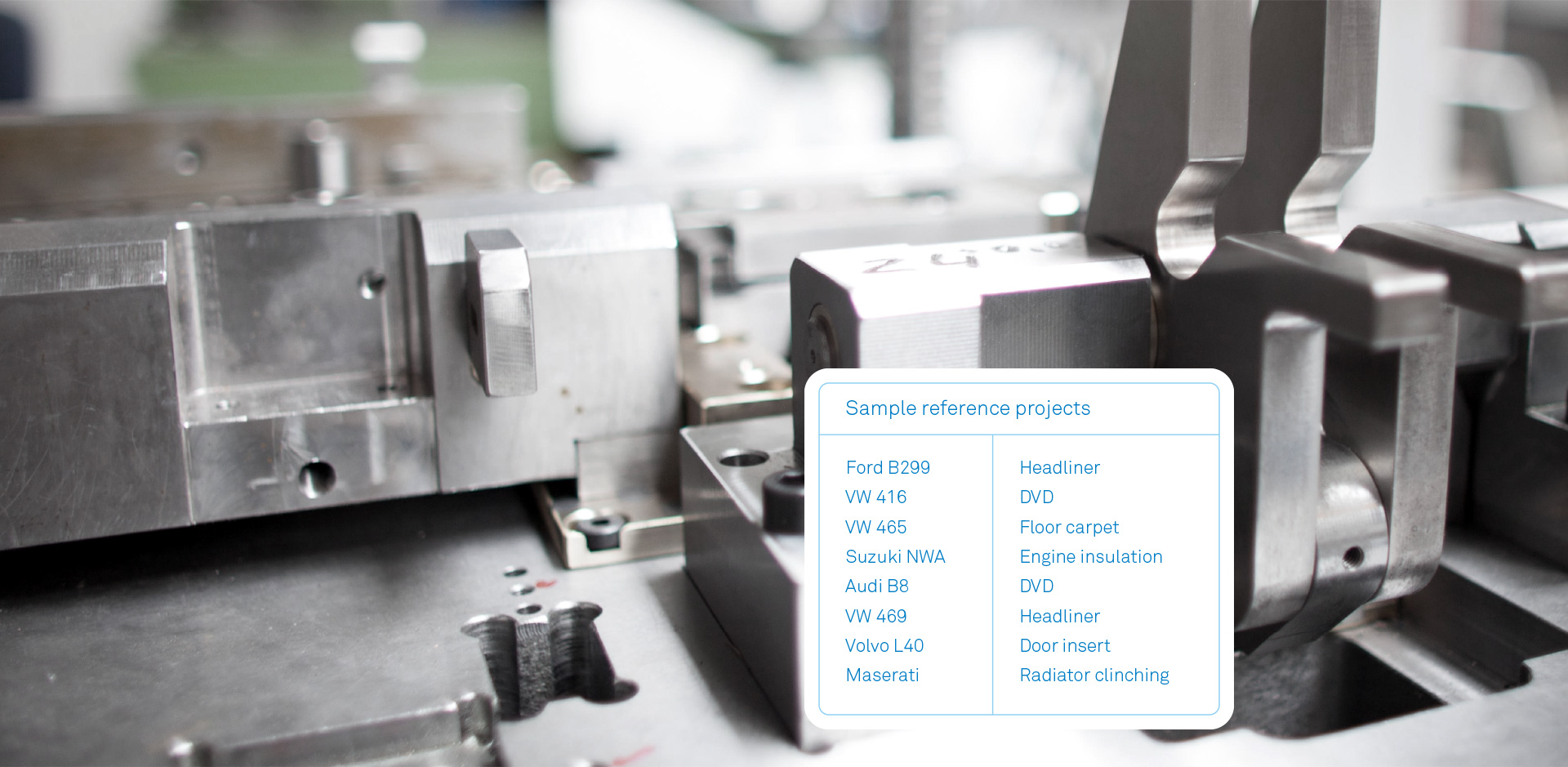

Press tools

Forming, covering, clinching, pinching. Impressive Know-How.

- Specialized tools for insulation and acoustic isolation parts.

- One-step for forming and punching/pinching technologies.

- Laser hardened cutting knives up to 60 HRC.

- Tools sizes up to 4,000 x 4,000 mm.